Product description, Technical parameters and configuration

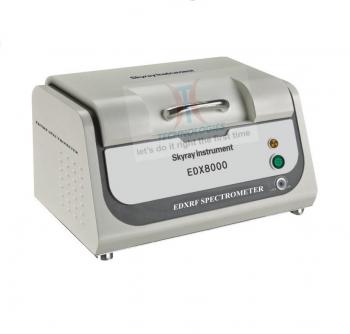

Instrument introduction

OES100VMI multi-channel (64channels at most), the OES is a new design developed by Skyray to give ferrous and non-ferrous metal a fast quantitative measurement. It provides an effective way for product quality control and can be widely applied in metallurgy, machinery and other industrial departments to fast analyze before forging and inspect centre laboratory products.

Performance characteristics

Fast Analysis

Excellent repeatability and stability

Excitation light source of high stability and the frequency is 150-600Hz. Different frequencies can be selected according to materials.

Variable element analysis: Al, Pb, Mg, Zn, Sn, Fe, Co, Ni, Ti, Cu and other basements.

Technical specifications

Optical system: Paschen-Runge

Concave grating: Radius of curvature 998.8mm

Etching density: 2160 L/mm

Wavelength range: 170-463nm

Reciprocal Ray Dispersion: 0.46nm/mm

Entry slit width: 20 μm

Exit slit width: 70μm

Max channels: 50

Constant temperature of spectrometer: 38°C

Spectrometer vacuum: less than 10Pa.

Optical chamber: vacuum, oil return prevention technology.

Constant temperature of optical system: 38℃±0.1℃;

Stimulated light source: High energy pre-spark technology; adjustable discharge parameter; computer control.

Spark platform: Argon-flushing-type stimulation chamber with the least argon gas

Power safety protection: Yes

Interface: Serial ports, USB

Upper computer : PC

Standard configurations

Data processing: Upload datum to computer through USB with much datum and fast speed. In addition, it is suitable for analysis before forging.

Multiplier phototube: transforms the optical signal (photons) into electric signal with high efficiency

Spark power supply: a pulse-control-type spark power supply with 15KV stably stimulated power.

Negatively high voltage power supply: Negatively high voltage power supply with well stability and load adjustment is developed by our company. The power supply can auto adjust itself according to the load weight.

Data processing control cell: use single-chip computer + field programmable gate array (FPGA) + USB interface to realize fast data collecting and processing.

Application fields

Fast quantitative analysis on ferrous and non-ferrous metals

Metallurgy, machinery and other industries

Fast analysis before forging and centre laboratory products inspection.

Analysis on variable elements: such as Al, Pb, Mg, Zn, Sn, Fe, Co, Ni, Ti, Cu